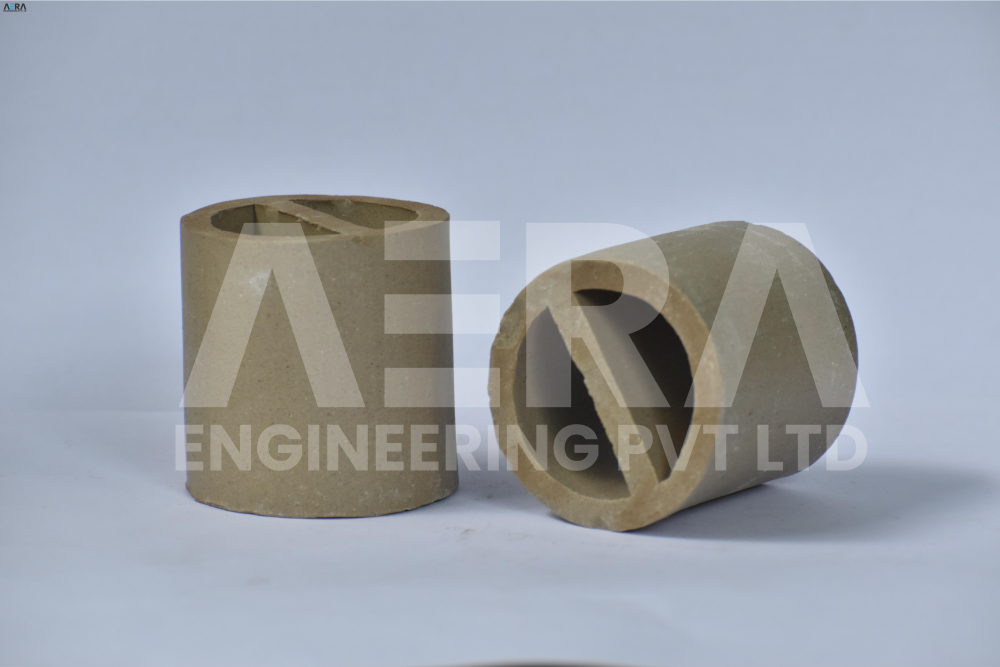

CERAMIC PARTITION RING

Ceramic partition rings, equivalent to ceramic partition packings or ceramic partition saddles, are structured packing materials used in various industrial processes, including distillation, absorption, and stripping columns. They are designed to enhance mass transfer and separation efficiency by providing a large surface area for contact between the liquid and gas phases.

Ceramic partition rings are typically cylindrical or tube-like structures with partitions or baffles inside. These partitions divide the interior of each ring into smaller compartments, creating additional surfaces for the liquid and gas to interact. The partitions can be in the form of radial ribs or axial blades, depending on the specific design and application requirements.

The use of ceramic materials, such as alumina, silicon carbide, or cordierite, in the construction of partition rings offers several advantages. Ceramic provides excellent chemical resistance, high-temperature stability, and mechanical strength, making it suitable for demanding industrial environments and processes involving corrosive or aggressive fluids.

The partitions or baffles in ceramic partition rings serve multiple purposes. They help to evenly distribute the liquid flow across the surface of the rings, preventing channeling or preferential flow paths. This promotes better contact between the liquid and gas phases, enhancing mass transfer efficiency and separation performance.

Furthermore, the partitions increase the surface area available for mass transfer and create a tortuous path for the liquid flow, facilitating improved mixing and distribution. The resulting turbulent flow promotes efficient interaction and contact between the phases, enhancing separation efficiency and reducing the risk of maldistribution.

Ceramic partition rings offer advantages such as low pressure drop, high operational stability, and resistance to fouling. They are particularly suitable for applications involving corrosive or high-temperature fluids, where their chemical resistance and thermal stability are crucial factors.

INQUIRE NOW