- HOME

- Pall Rings by Aera Engineering Pvt Ltd: Elevating Mass Transfer Efficiency in Industrial Processes

Pall Rings by Aera Engineering Pvt Ltd: Elevating Mass Transfer Efficiency in Industrial Processes

Pall Rings by Aera Engineering Pvt Ltd: Elevating Mass Transfer Efficiency in Industrial Processes

- Posted by Admin

- Nov 04 ,2023

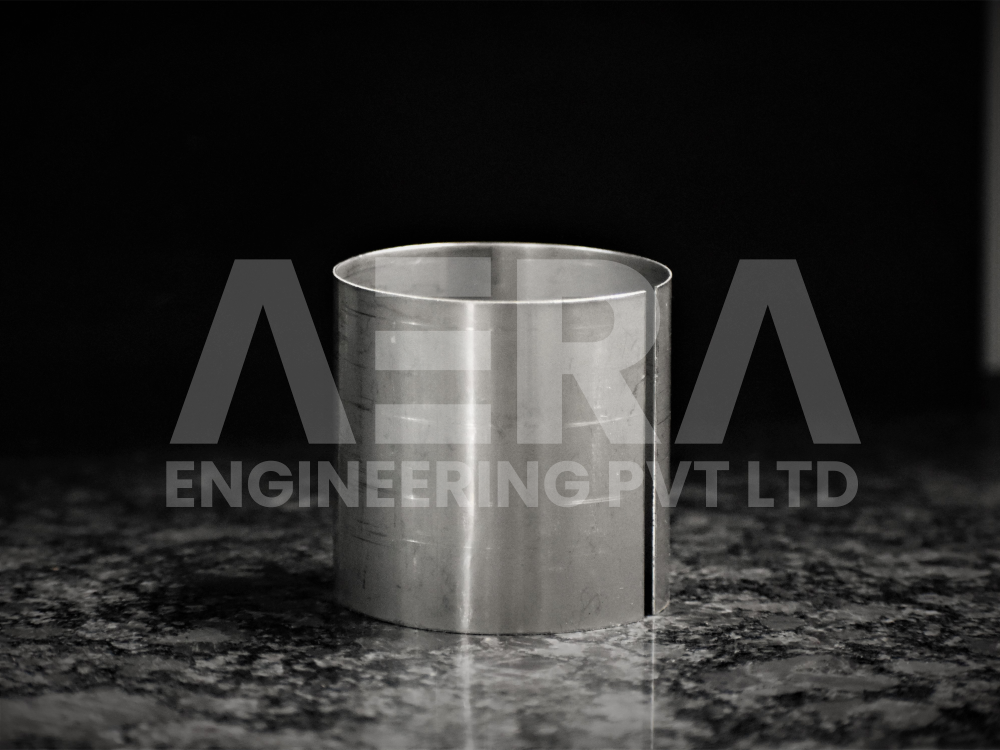

- In the realm of industrial processes, achieving optimal mass transfer efficiency is crucial for improving separation and purification results. When it comes to enhancing gas-liquid contact and streamlining mass transfer, one name stands out prominently: Pall Rings. These cylindrical-shaped packing elements have become renowned for their exceptional mass transfer capabilities and versatility in various industrial applications. In this blog, we explore the remarkable features of Pall Rings and their role in elevating mass transfer efficiency, with a special focus on the high-quality products offered by Aera Engineering Pvt Ltd.

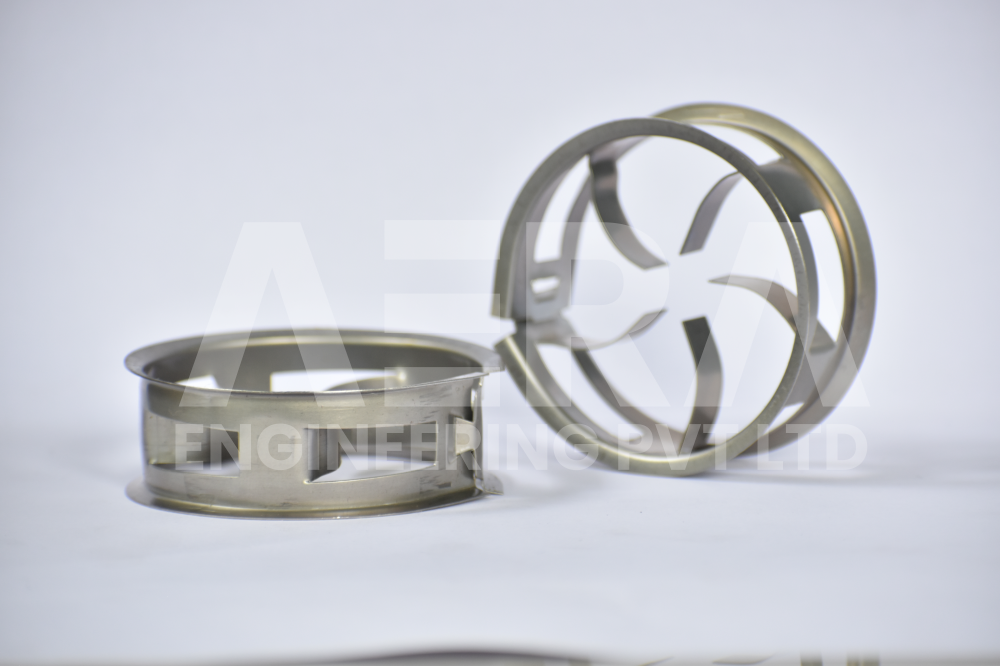

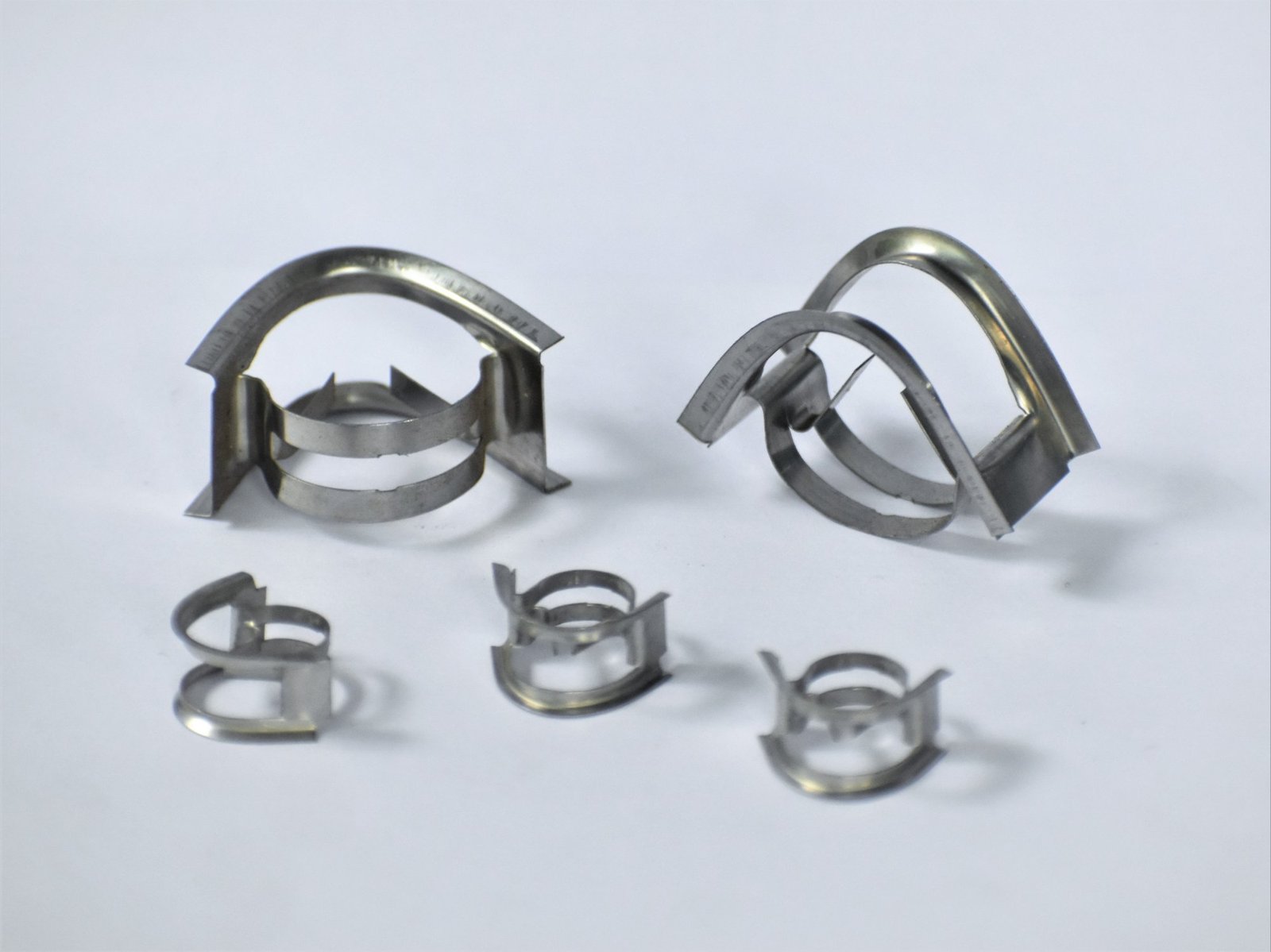

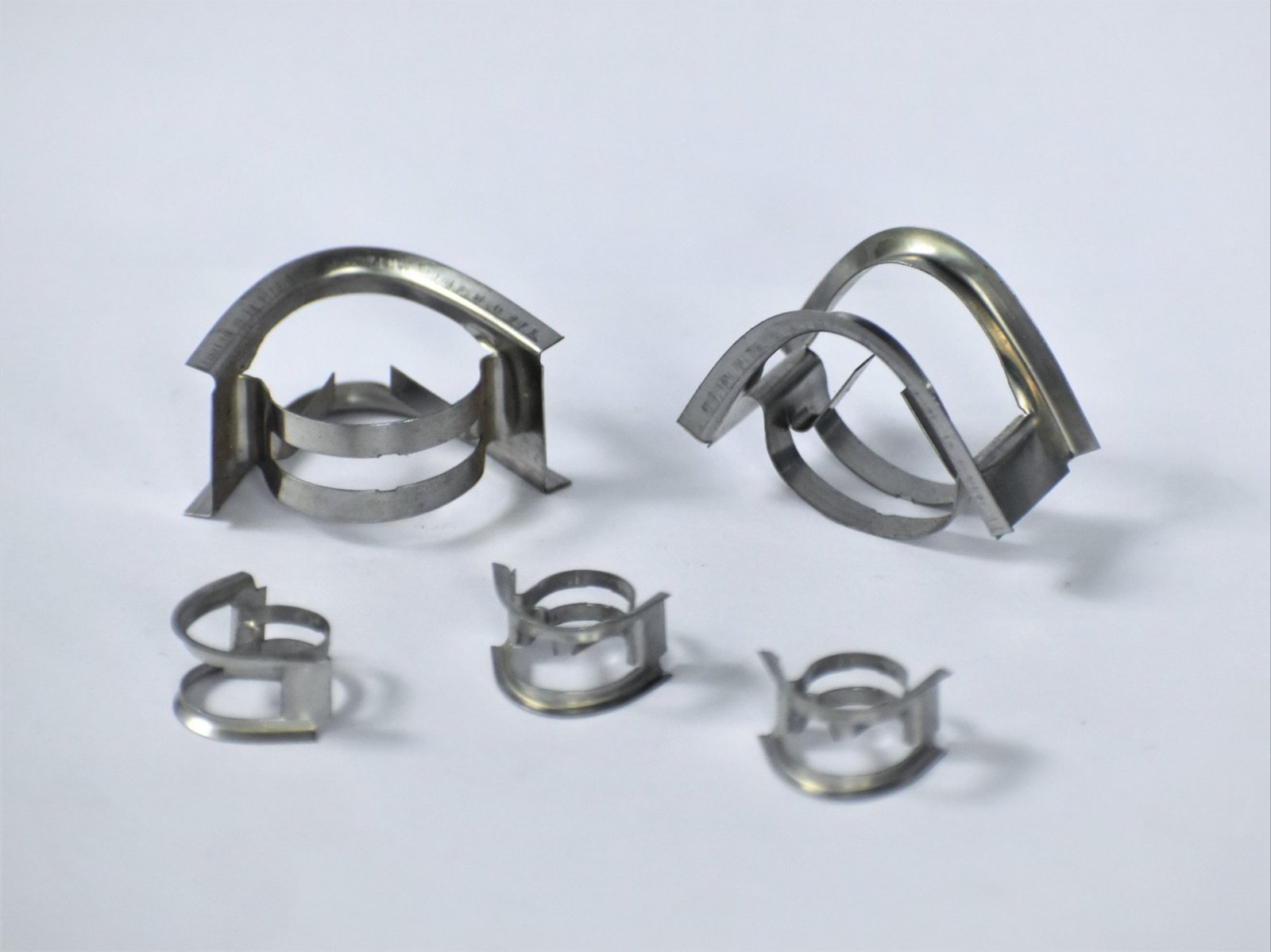

The Geometry of Efficiency

- Pall Rings are engineered with a unique geometric design that sets them apart from traditional packing materials. Their cylindrical shape is adorned with inward and outward protrusions, creating an intricate network of crevices and voids. This design effectively increases the surface area available for gas-liquid contact, a key factor in optimizing mass transfer efficiency. The result is a higher rate of exchange between the phases, which translates into improved performance across a range of industrial processes.

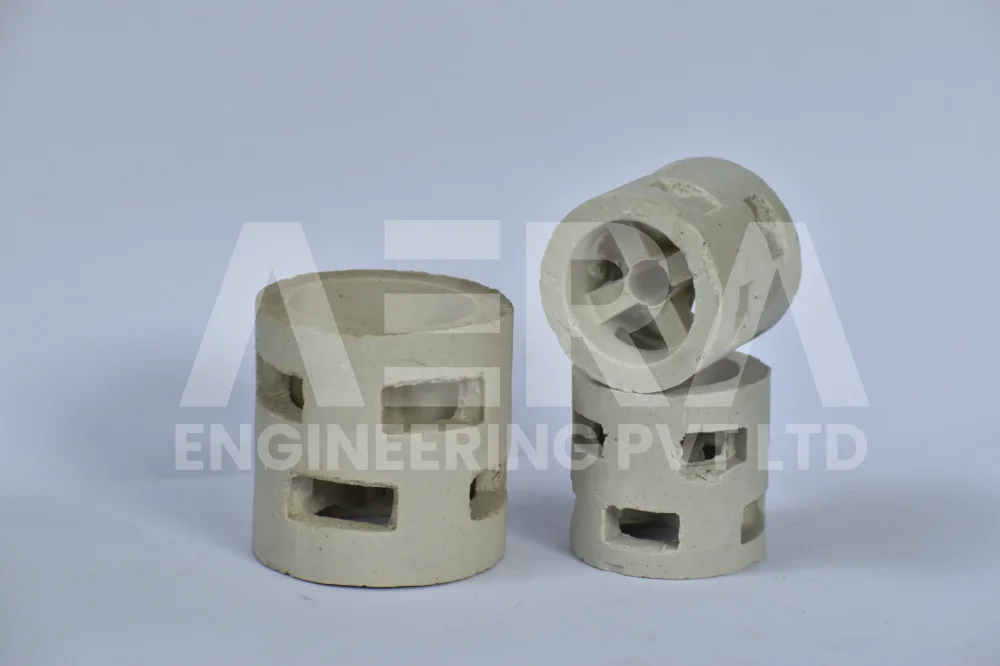

High-Quality Manufacturing

- The success of Pall Rings in industrial applications is largely attributed to their precise manufacturing and the use of top-quality materials. Companies like Aera Engineering Pvt Ltd have mastered the art of crafting Pall Rings with precision, ensuring the highest level of quality and performance. These rings are designed to withstand the most demanding operating conditions, offering excellent resistance to chemical corrosion and thermal stress. This longevity and reliability are key advantages, as they reduce the need for frequent replacements and maintenance, ultimately leading to cost savings.

Uniform Flow and Reduced Pressure Drop

- One of the key characteristics of Pall Rings is their optimized distribution within the packing column. This strategic arrangement ensures a uniform flow of both liquid and gas through the column, minimizing pressure drop. In comparison to traditional packing materials, Pall Rings stand out for their ability to maintain a stable flow profile. The reduction in pressure drop not only conserves energy but also ensures that the mass transfer process remains efficient over extended periods.

Versatile Applications

- Pall Rings have proven their worth in a wide range of industrial processes, making them a versatile choice for engineers and operators. Whether you are involved in distillation, absorption, stripping, scrubbing, or any other mass transfer operation, Pall Rings excel at facilitating efficient separation and improving overall process performance. Their versatility has made them an indispensable component in industries such as chemical manufacturing, petrochemicals, wastewater treatment, and more.

Partnering with Aera Engineering Pvt Ltd

- When it comes to choosing the right Pall Rings for your industrial processes, partnering with a reputable supplier is essential. Aera Engineering Pvt Ltd is a trusted name in the industry, known for its commitment to quality and customer satisfaction. Their Pall Rings are meticulously manufactured to meet the highest standards, ensuring that you receive a product that delivers exceptional performance and longevity.

Conclusion

- In the world of mass transfer efficiency, Pall Rings have earned their reputation as a game-changing packing material. Their geometric design, high-quality manufacturing, uniform flow characteristics, and versatile applications make them a go-to choice for industries seeking optimal performance. If you are looking to elevate mass transfer efficiency in your industrial operations, consider Pall Rings from Aera Engineering Pvt Ltd. Unlock the potential of your processes, achieve superior separation, and purification results, and experience the difference that quality and precision can make.

Recent Posts